Predictive vs Preventive: In-depth Maintenance Guide for 2024

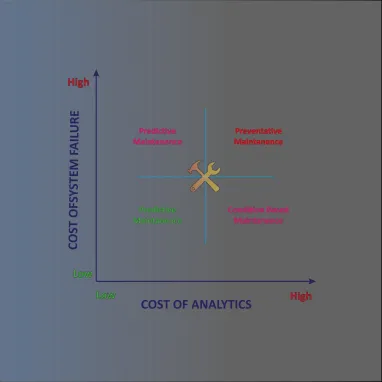

As you can see above, if setting up analytics is not more costly than reduced uptime, then predictive analytics is the solution.

Let’s look at why. Most executives are not clear on how predictive is different than preventive maintenance they have been conducting for years. Both approaches aim to prevent unexpected breakdowns, increase uptime and useful life of machines. However, they have different cost structures and they require different capabilities from the organization.

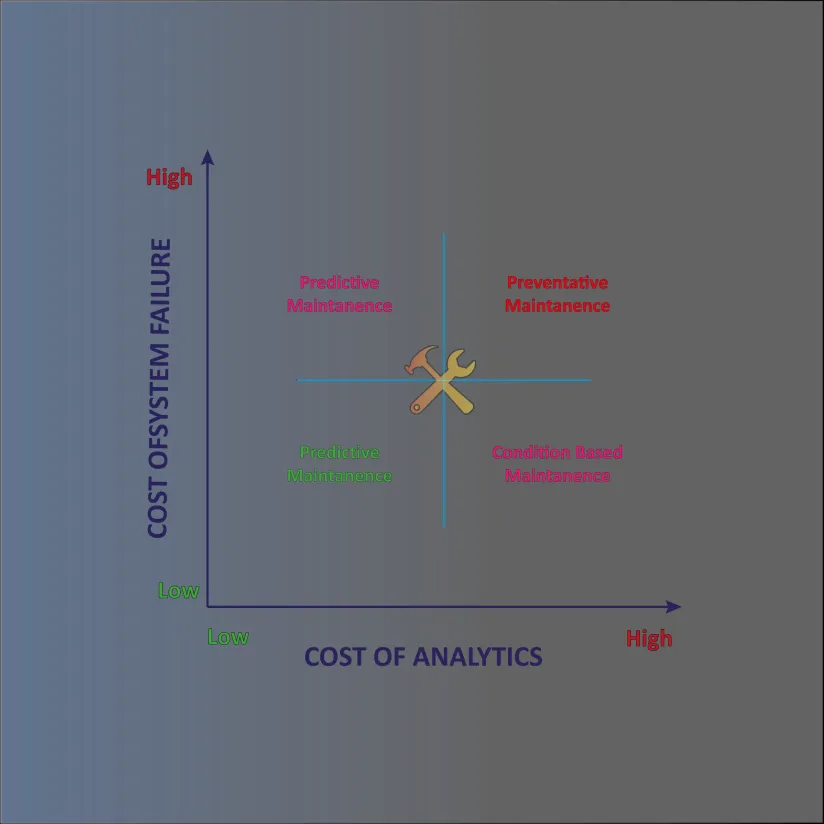

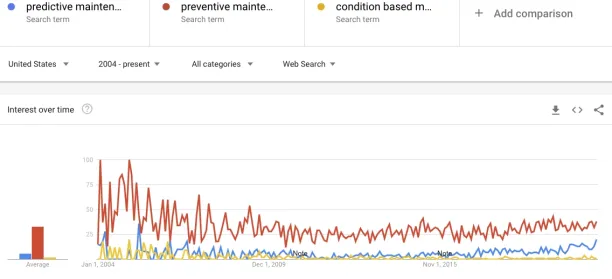

Predictive maintenance vs preventive maintenance: Which one is growing in popularity?

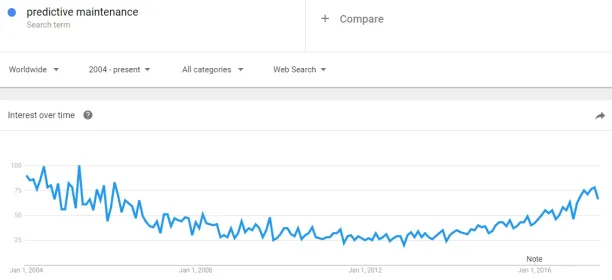

An easy way to decide is to go with the more popular solution or the solution that is increasing in popularity. And a proxy for that is the frequency with which people search for these solutions in the search engines. As you can see below, predictive maintenance is growing in popularity:

Predictive maintenance

Maintenance is the required effort and cost to optimize machine useful life and performance. Following predictive maintenance approach requires real time monitoring of machines and robots. Maintenance is performed when issues are detected that are expected to impact performance in the future.

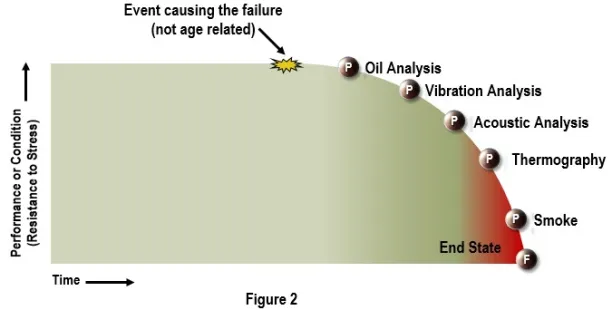

P-F interval is generally used to explain how maintenance works. As you can see below, event causing failure happens at a time difficult to estimate based on the machine’s age, environment, parameters and inputs. However, after this event happens, several diagnostic techniques to monitor machine condition are available in predictive maintenance solutions that can uncover this event. Such techniques include:

- Oil analysis

- Vibration analysis

- Acoustic analysis

- Thermography

Based on how different machines take part in production, some failed states may not lead to any production issues while other failed states can have significant financial results. For example, Fero Labs’, an industrial analytics vendor, solution considers states of multiple machines and their role in production to conduct predictive maintenance. For example, predictive maintenance to prevent failures with limited financial impact can be delayed to optimize staffing and production schedule. However, predictive maintenance of critical machines would need to be performed immediately.

Pros

- Improves up-time

- Prolongs hardware useful life

- Improves product quality and reduces waste as machines are utilized in better conditions

- Improves worker and environmental safety by reducing catastrophic failures

- Reduces maintenance costs over preventive maintenance by 8-12% according to Department of Energy’s estimates. Maintenance will only be completed when predicted

- be planned preventing inefficiencies due urgent resource allocation in case of machine failure

- be focused on parts with possible malfunctions further reducing maintenance effort.

Cons

- In some cases, requires installing sensors to monitor existing machinery

- Requires setting up analytics capabilities which can be expensive for some businesses

- Staff training needed to change maintenance process

In short, predictive makes sense when the investment for analytics engine is worth the improvement in up time and cost reduction in maintenance.

As you can see below from Google trends, predictive maintenance is a bit ahead in the hype cycle, having passed its peak buzz levels around 2004. Now is the time for adoption of predictive maintenance to increase. Check out our extensive article for more on predictive maintenance such as its quantitative benefits.

Preventive maintenance

Preventative maintenance or preventive maintenance is also called planned maintenance and requires performing maintenance at intervals specified by the manufacturer or maintenance personnel. Most of the time preventive maintenance follows a regular schedule to make it easy to track. However, the same machine operating in different conditions requires quite a different maintenance schedule and setting the right maintenance schedule is quite difficult.

For example, I was working with a network management company maintaining base stations for the mobile network in the US. Even though, there was a variety of atmospheric conditions within their defined regions like California, company stuck to the same maintenance schedule for all stations in a region. This practice leads to either more or less than the required maintenance.

Therefore, preventive maintenance inevitably leads to one of two scenarios compared to predictive maintenance:

- Over-maintenance: Maintenance costs will be high due to unnecessary maintenance. Sadly, maintenance is not only costly, also requires machines to be stopped and restarted which is an unnecessary strain on the machine. Further unnecessary maintenance can lead to unintended damage on the machine.

- Under-maintenance: Under-maintained equipment will likely lead to longer downtime and unexpected failures. Failures can be disruptive especially if spare parts are required to fix the machine. Overstocking of spares increase inventory costs while not having the necessary spares can mean days of down time.

Pros

- Reduces maintenance costs over reactive maintenance by 12-18% according to Department of Energy’s estimates. Fewer failures will lead to fewer expenses like spare parts.

Cons

- Catastrophic failures are possible.

- Labor intensive process

Preventive maintenance can be a good solution when the investment for analytics engine is not worth the improvement in up time.

Condition based maintenance

In short, poor man’s maintenance! Also called corrective or reactive maintenance, issues are fixed after they arise in this model. Makes sense for hardware for which loss of uptime is not that costly.

There are 2 types of corrective maintenance:

- Immediate corrective maintenance: Maintenance starts immediately after a malfunction is detected.

- Deferred corrective maintenance: Maintenance work is delayed in line with maintenance rules

Pros

- Requires minimal staffing

Cons

- Catastrophic failures are likely

- Increased maintenance cost as failures create need for new spare parts and extensive repair

- Reduced downtime

The appropriate maintenance for your business

Given the definitions, the advantages of predictive maintenance should be clear. Especially in an industrial setting with costly machines with limited redundancy, predictive maintenance makes sense. Reducing downtime for a robot park can save a lot more than the cost of setting up an analytics system.

However, predictive is not the ideal solution for any system. According to Department of Energy’s report, As of 2010 >85% of US businesses were relying on reactive or preventive maintenance.

You can also check our list of predictive maintenance software to find the most suitable option.

To hear from those who benefit from installing predictive maintenance systems, please take a look at our blog post on the topic explaining how to implement predictive maintenance. If you are ready to work with preventive maintenance companies,

Cem has been the principal analyst at AIMultiple since 2017. AIMultiple informs hundreds of thousands of businesses (as per similarWeb) including 60% of Fortune 500 every month.

Cem's work has been cited by leading global publications including Business Insider, Forbes, Washington Post, global firms like Deloitte, HPE, NGOs like World Economic Forum and supranational organizations like European Commission. You can see more reputable companies and media that referenced AIMultiple.

Throughout his career, Cem served as a tech consultant, tech buyer and tech entrepreneur. He advised businesses on their enterprise software, automation, cloud, AI / ML and other technology related decisions at McKinsey & Company and Altman Solon for more than a decade. He also published a McKinsey report on digitalization.

He led technology strategy and procurement of a telco while reporting to the CEO. He has also led commercial growth of deep tech company Hypatos that reached a 7 digit annual recurring revenue and a 9 digit valuation from 0 within 2 years. Cem's work in Hypatos was covered by leading technology publications like TechCrunch and Business Insider.

Cem regularly speaks at international technology conferences. He graduated from Bogazici University as a computer engineer and holds an MBA from Columbia Business School.

To stay up-to-date on B2B tech & accelerate your enterprise:

Follow onNext to Read

Top 15 Predictive Maintenance Tools & Selection Guide in 2024

Predictive Maintenance (PdM): Benefits & How it Works in 2024

My husband and I are opening a warehouse for our business, so I wanted some maintenance tips. I didn’t know oil analysis counted as a predictive solution that’ll prolong your equipment’s lifespan. I’ll have to keep that in mind as I buy the rest of the industrial equipment we need, so my husband and I can save money and time in the future with our machines!

Comments

Your email address will not be published. All fields are required.